Powder Coating is a multistep method used to finish products and give them a long-lasting and robust coating.

1. The product is cleaned and prepared for coating. It is common for blast cabinets and other power blasters to be used for this step.

2. The product is then coated with a fine powder that covers the product’s surface.

3. The coated product is moved into a curing oven where it is heated. Heating the powder allows it to melt and flow into a more uniform coating that adheres to the product.

4. Once the melted powder cools and hardens, it creates an extremely durable and attractive coating around the finished product.

What sort of systems are used for powder coating?

All powder coating systems have three different types of equipment that are necessary to ensure a professional final product.

- Pretreatment equipment: to clean the product before coating with powder

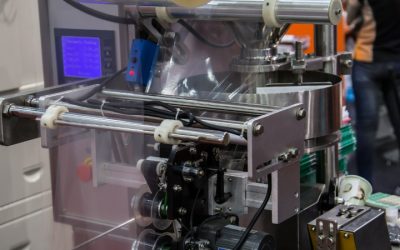

- Application equipment: to spray the powder onto the product

- Curing equipment: to cure the powder into a durable final coating

How does one set up their powder coating system?

There are two common configurations for any powder coating system. These are called batch powder coating line and automated powder coating line.

A batch powder coating line is often a system where products are prepared, coated, and cured in batches so large that operators will handle up to dozens or hundreds of parts at a time. Batch powder systems are often maintained manually.

An automated powder coating line runs in a similar manner to the batch coating system, but instead on relying on operators manually moving each product through the varying levels of production, the parts are moved on conveyor belts from one stage to the next.

It is important that one considers the needs of their business in order to decide which system is best for them.